Sunday was spent trying to get the gas tank back together in one piece again and get the inside coated to prevent rust and scale. It's been months since I worked on it so you can read all about it here: Gas Tank. The coating method was a product called Kreem and it is designed for this purpose. The famous mechanic in Fort Stockton, Joe Henderson, has used this product with great success and has tanks that are over 8 years old with this coating.

The process is a PITA and working a big heavy tank isn't fun. I am not sure that I did the best job of coating it, but it is done and if this becomes a future problem, it will be scrapped and stainless will enter the equation. I was going to change up the brackets that I made for it 25 years ago, but then I saw all the extra work involved and realized I would be doing a lot for little gain.

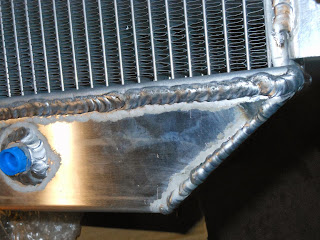

The Champion Radiator came in and looked to be in good order except for one area that had some damage from the factory. It's not bad and the tubes look a little damaged but ok. This is a 3 row because they were out of 2 rows.